|

|

Задание №3 – Патентный Поиск.

1.Для одного из определенных при выполнении Задания №1 предметов, вещей – объектов материального мира, в целом или частично, которые были отнесены к изобретениям, провести поиск патентных документов в четырех базах:

- Укрпатента;

- Роспатента;

- Патентного ведомства США (U.S. Patent and Trade Office);

- Европейского патентного ведомства (European Patent Office).

Цель – отобрать патентные документы, наиболее близкие с технической точки зрения к выбранному объекту исследования.

2. Поиск проводить с использованием ключевых слов рубрик Международной Патентной Классификации, определенных при выполнении Задания №2.

3. В результате поиска в каждой базе должно быть сделано следующее:

- описание объекта анализа для каждой базы;

- описание осуществленных процедур поиска с обозначением ключевых слов и МПК;

- перечень релевантных патентных документов с обозначением наиболее близких;

- полное описание патента.

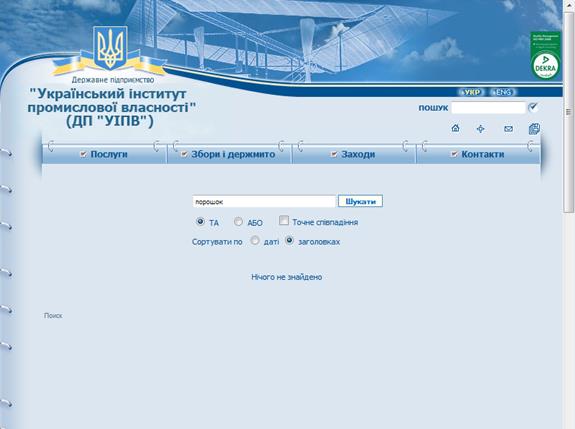

Укрпатент

В Укрпатенте по ключевым словам результатов не найдено.

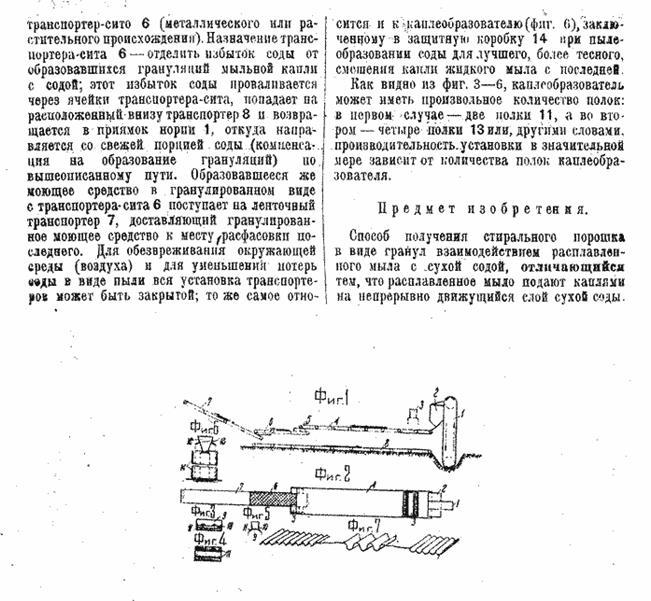

Роспатент

Роспатент. Найдено 5 документов приблизительно одинаковой релевантности.

Патентное ведомство США

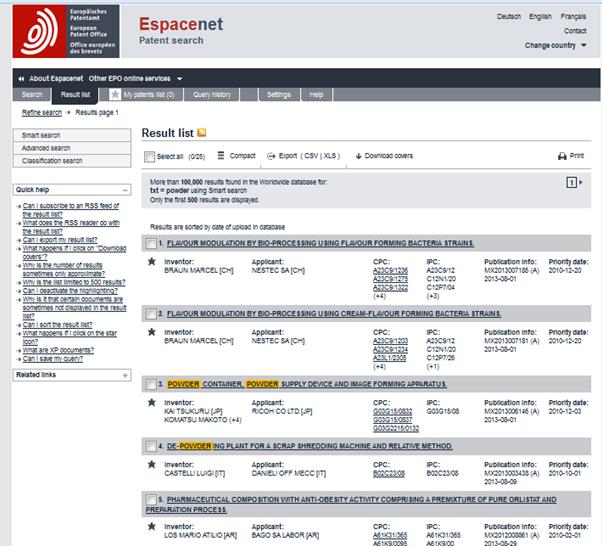

Европейское патентное ведомство

What is claimed is:

1. A powder laundry detergent composition comprising:

a. from about 55% to about 95% by weight of detergent base particles, wherein the detergent base particles comprise

i. from about 5% to about 80% by weight of an inorganic carrier selected from the group consisting of phosphates and carbonates;

ii. from about 0.1% to about 90% by weight of a detergent surfactant selected from the group consisting of nonionic surfactants and wherein the nonionic surfactant is the sole detergent surfactant;

b. from about 0.1% to about 15% by weight of separate acidulant particles, wherein the acidulant particles are fumaric acid; and,

c. from about 0.1% to about 30% by weight of separate solid homogeneous whitening agent particles comprising a whitener and a whitening agent surfactant.

2. The detergent composition of claim 1 wherein the inorganic carrier is an alkali metal carbonate.

3. The detergent composition of claim 1 wherein the nonionic surfactant has the formula R.sup.1 (OC.sub.2 H.sub.4).sub.n OH, where R.sup.1 is a C.sub.8 -C.sub.18 alkyl group or a C.sub.8 -C.sub.12 alkyl phenyl group, and n is from 3 to about 80.

4. The detergent composition of claim 1 wherein the ratio of inorganic carrier to acidulant particles is from about 2:1 to about 15:1.

5. The detergent composition of claim 1 wherein the ratio of detergent surfactant to whitening agent particles is from about 2:1 to about 40:1.

6. The detergent composition of claim 1 wherein the whitening agent particles further comprise water.

7. The detergent composition of claim 1 wherein the ratio of whitening agent surfactant to whitener is from about 1:1 to about 50:1 such that the particle reduces degradation of the whitener.

8. The detergent composition of claim 1 wherein the solid homogeneous whitening agent particles comprise:

a. from about 1% to about 50% by weight of a whitener;

b. from about 50% to about 95% by weight of a whitening agent surfactant selected from the group consisting of anionics, nonionics, zwitterionics, ampholytics, cationics, and mixtures thereof that are solids in a temperature range of from about 32 180

c. from about 0.1% to about 10% by weight of water.

9. The detergent composition of claim 8 wherein the whitener is selected from the group consisting of diaminostilbenedisulfonic acids, diaminostilbenedisulfonic acid-cyanuric chlorides, and mixtures thereof.

10. The detergent composition of claim 9 wherein the whitening agent surfactant is an anionic surfactant.

11. The detergent composition of claim 10 wherein anionic surfactant is selected from the group consisting of alkali metal, ammonium and alkylolammonium salts of organic sulfuric reaction products having in their molecular structure an alkyl group containing from about 8 to about 20 carbon atoms and a sulfonic acid or sulfuric acid ester group.

12. The detergent composition of claim 8 wherein the ratio of whitening agent surfactant to water is from about 5:1 to about 70:1.

13. A phosphate-free powder laundry detergent composition comprising:

a. from about 55% to about 95% by weight of agglomerated detergent particles comprising from about 5% to about 80% by weight of an alkali metal carbonate and from about 1% to about 90% by weight of a nonionic detergent surfactant, wherein the nonionic detergent surfactant is the sole detergent surfactant present;

b. from about 0.1% to about 15% by weight of separate acidulant particles, wherein the acidulant particles are fumaric acid; and,

c. from about 0.1% to about 30% by weight of separate solid homogeneous whitening agent particles with the particles comprising from about 1% to about 50% by weight of a whitener; from about 50% to about 95% by weight of a whitening agent surfactant selected from the group consisting of anionics, nonionics, zwitterionics, ampholytics, cationics, and mixtures thereof that are solids in a temperature range of from about 32 (0 0.1% to about 10% by weight of water.

14. A method of making a detergent composition comprising the steps of:

a. providing powder laundry detergent base particles, wherein the particles comprise from about 5% to about 80% by weight of an inorganic carrier selected from the group consisting of phosphates and carbonates and from about 1% to about 90% by weight of a detergent surfactant selected from the group consisting of nonionic surfactants and wherein the nonionic surfactant is the sole detergent surfactant;

b. admixing from about 0.1% to about 15% by weight of the detergent composition, acidulant particles to the detergent base, wherein the acidulant particles are fumaric acid; and,

c. admixing from about 0.1% to about 30% by weight of the detergent composition solid whitening agent particles to the detergent base, wherein the solid whitening agent particles comprise a whitener and a whitening agent surfactant.

15. The method of claim 14 wherein the inorganic carrier is an alkali metal carbonate.

16. The method of claim 14 wherein the nonionic surfactant has the formula R.sup.1 (OC.sub.2 H.sub.4).sub.n OH, where R.sup.1 is a C.sub.8 -C.sub.18 alkyl group or a C.sub.8 -C.sub.12 alkyl phenyl group, and n is from 3 to about 80.

17. The method of claim 14 wherein the ratio of inorganic carrier to acidulant particles is from about 2:1 to about 15:1.

18. The method of claim 14 wherein the ratio of detergent surfactant to whitening agent particles is from about 2:1 to about 40:1.

19. The method of claim 18 wherein the whitening agent particles further comprise water.

20. The method of claim 18 wherein the ratio of whitening agent surfactant to whitener is from about 1:1 to about 50:1 such that the particle reduces degradation of the whitener.

21. The method of claim 14 wherein the solid whitening agent particles comprise:

a. from about 0.1% to about 50% by weight of a whitener;

b. from about 50% to about 95% by weight of a whitening agent surfactant selected from the group consisting of anionics, nonionics, zwitterionics, ampholytics, cationics, and mixtures thereof that are solids in a temperature range of from about 32 180

c. from about 0.1% to about 10% by weight of water.

22. The method of claim 21 wherein the whitener is selected from the group consisting of diaminostilbenedisulfonic acids, diaminostilbenedisulfonic acid-cyanuric chlorides, and mixtures thereof.

23. The method of claim 22 wherein the whitening agent surfactant is an anionic surfactant.

24. The method of claim 23 wherein the anionic surfactant is selected from the group consisting of alkali metal, ammonium and alkylolammonium salts of organic sulfuric reaction products having in their molecular structure an alkyl group containing from about 8 to about 20 carbon atoms and a sulfonic acid or sulfuric acid ester group.

25. The method of claim 21 wherein the ratio of whitening agent surfactant to water is from about 5:1 to about 70:1.

26. A method for making a phosphate-free detergent composition comprising the steps of:

a. agglomerating a mixture comprising from about 5% to about 80% by weight of an alkali metal carbonate and from about 1% to about 90% by weight of a nonionic detergent surfactant wherein the nonionic detergent surfactant is the sole detergent surfactant present;

b. drying the mixture to form powdered particles;

c. adding to the powdered particles from about 0.1% to about 15% by weight of the detergent composition solid acidulant particles, wherein the acidulant particles are fumaric acid; and,

d. adding to the powdered particles from about 0.1% to about 30% by weight of the detergent composition separate solid whitening agent particles wherein the solid whitening agent particles comprise a whitener and a whitening agent surfactant.